What is best power tools?

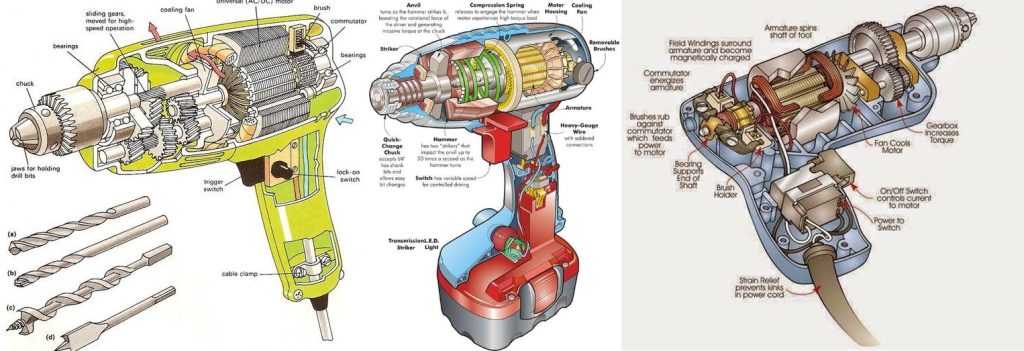

Principle of power tools

- “electric” is literally understood to be plugged in to work; Usually, after plugging in, the motor inside the machine is driven to run before it starts to convert into kinetic energy.

- after plugging in, why does the electric machine inside the machine run? So the core part is the motor; The core of motor consists of rotor armature and stator stator; By plugging it in, they generate a magnetic field to make the Motor run at high speed and generate kinetic energy output to make the whole machine work; (The motor structure is explained in detail later)

- as for some not plugged in; For example, gasoline, lithium battery, these principles are the same, but their initial source of kinetic energy is not the same, so in the tool is just different classification, use is different;

Basic structure of power tools:

General class power tools: All tool classes are basically included:

A: Outer case:

The material is usually nylon PA66; Or PC carbon material, mostly nylon material;

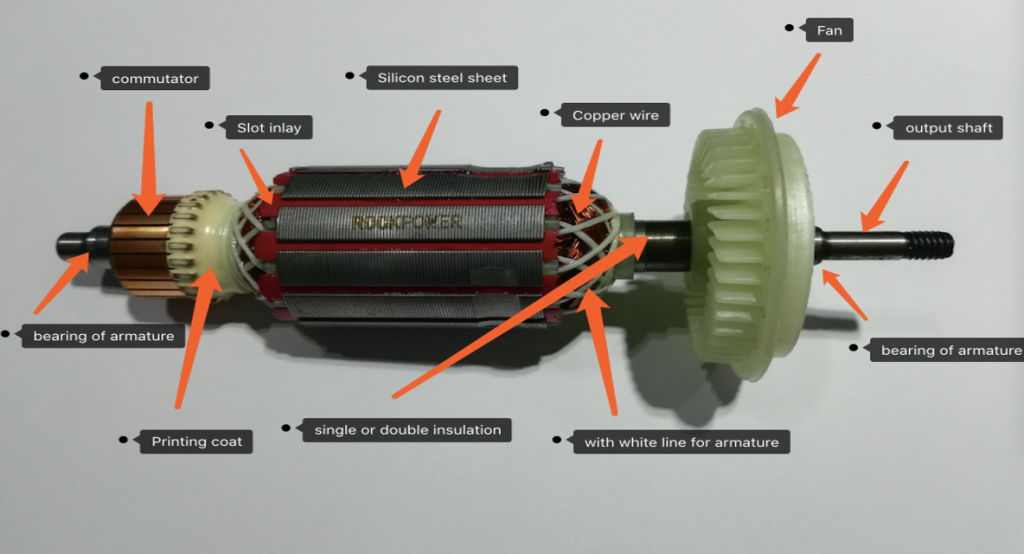

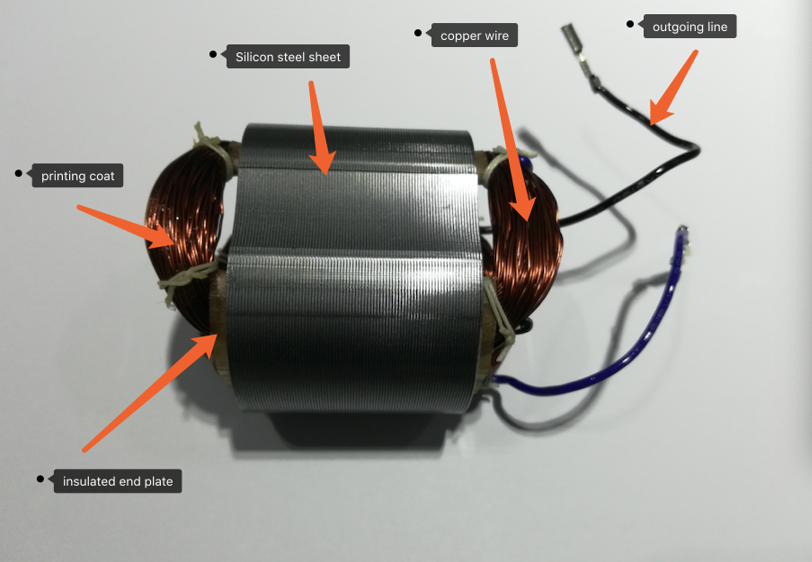

B: Amature and stator:

It is the core part of the tool, that is, the main part of the motor, and some technical parameters must be skilled in communicating with customers to have a certain degree of persuasion.

What is best power tools? the key points that make a professional power tool:

- Copper Wire: Armature Copper wire 200 degrees high temperature line, followed by 180 degrees high temperature line, 150 degrees high temperature line, our industrial quality is usually used 200 degrees high temperature line.

- Stator enameled wire: 200 degrees, 180 degrees, slightly general with 150 degrees high temperature line, our industrial quality is usually used 180 degrees high temperature line;

- Silicon Steel Sheet, normally model #800(quality is OK), #600(quality is better than #800); #470(quality is best). Normally electric tools use #800 is enough, very high quality may choose #600.But some very low price in market, they usually made of steel strip – that is, some silicon steel sheet scraps, so the cost is reduced a lot. But the quality can also be basically stable;

- Carbon Brush: Good carbon brush wear resistance and small spark;

- Switch: Switch quality is also very important, the current selection is usually the factory fixed cooperation switch factory

- Bearing: Usually the bearing at both ends of the rotor is good enough to use the brand, which can save a lot of costs;

- Cable: material PVC cable and rubble cable rubber wire; But to the Southeast Asian market, many customers currently like the kind of rubber wire that is very thick outside (similar to rubber wire) – the cost is much cheaper than rubber wire, but it looks like rubber wire,(rubber wire wear-resistant, strong protective effect); To the European and American markets are usually PVC cable/ rubble cable; There is no use of pixel lines, because of safety issues;Many factories make very cheap machines sometimes use copper-clad aluminum cables;

About Certification of power tools:

About Voltage of Power Tools:

Southeast Asia:

1), China is 220v, but in the international standard mark: 230v-250v; Frequency: 60Hz;

2), most countries in Southeast Asia voltage is 230v-250v; Frequency: 60Hz;

3), Japan, Taiwan: 110v; But in the international usually also marked: 127v; Frequency 50Hz-60Hz;

USA: 110v(127v); Frequency 50Hz-60Hz;

Europe: 230v-250v; 60Hz;

South America: 110v in some countries; Part is 230v-250v; For example, the southern and northern parts of Brazil are 110v and 230v respectively;

Eastern Europe: 230v-250v; 60Hz;

Middle East and other countries: 230v-250v; 60Hz;

Why there are two kinds of voltage in the world: mainly related to the evolution history of each country; But here’s the difference: 110v low voltage is much safer; 230v high voltage safety is low; That is, if a person is electrocuted, low pressure is much less likely to cause an accident.

Click to see other questions about Angle grinder:

Related Products:

Click here to see more Video

Product Details

Descriptions about Impact Drill

Exhibition Pictures

The goods are packed according to customer special requirement. The shipping is fast and safe.

Factory Warehouse

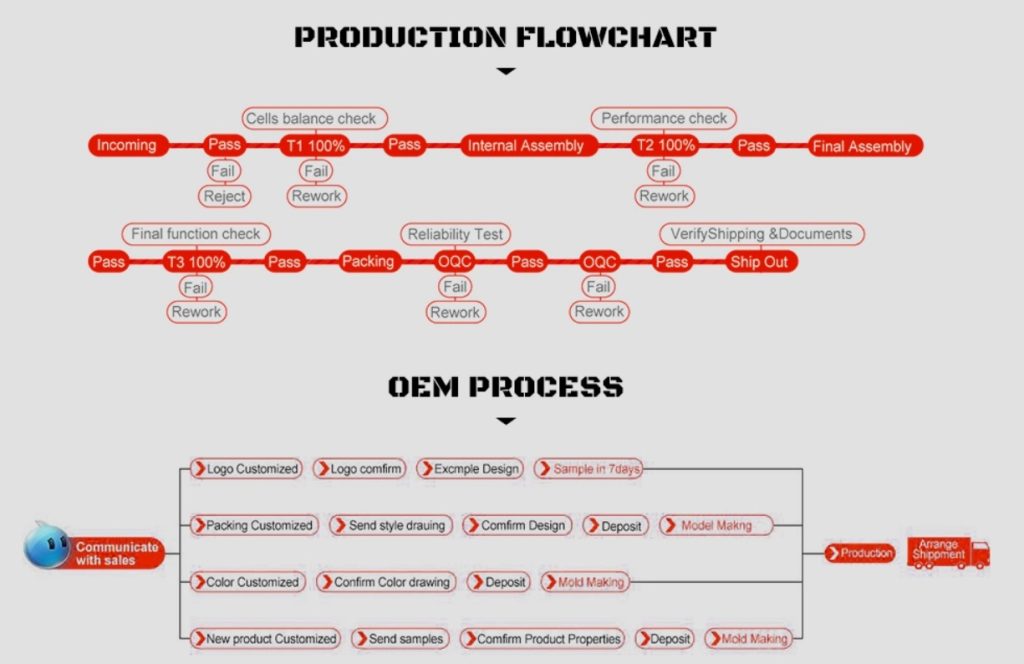

This is the process flow chart and OEM process flow chart. For details please contact with our sales.

FAQ

Pleas contact with us if you can not find your answer in FAQs.