Cut Off Tool vs Angle Grinder

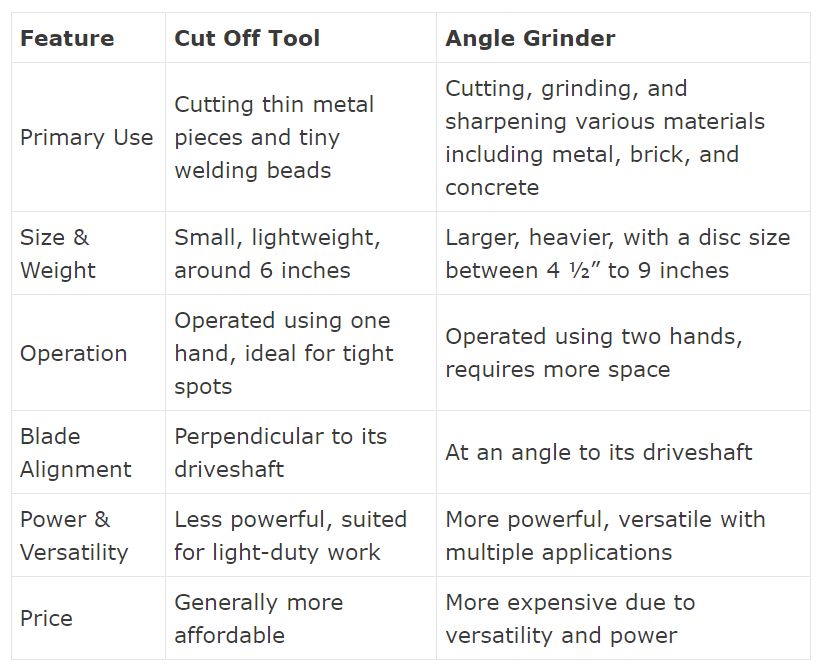

Although Cut Off Tool and Angle grinders may look similar, there are key differences between them that can significantly affect how well they perform certain tasks. They are not substitutable. People sometimes ask about using an Angle grinder or cutting tool more often, because every DIY enthusiast knows that the right tool isn’t cheap. In essence, Angle grinders are more adaptable than cutting tools that can only cut. However, cutting tools are usually more precise and suitable for delicate tasks.

But there is more to it than that. In this article, I will compare the cutting tool with the Angle grinder. We’ll also demonstrate how to choose between the two so you can decide which one is best for your toolbox (and your wallet). When deciding whether to use an Angle grinder or a cutting tool, the main factor to consider is the purpose of the tool. Angle grinders are commonly used to grind, cut and polish materials such as metal or stone. Cutting tools are usually used for thin materials such as metal sheets, pipes, rods or bolts.

Cut Off Tool

A cutting tool is a small one-handed power tool used to cut metal or sharpen metal parts, they are usually equipped with a motor of about 1 HP and a cutting disc aligned at right angles. They can also be used to cut a variety of other materials that require extra strength or precision. The cutting tool can be easily operated with one hand and is available in wired and wireless versions. The cutting attachment is placed at a 90-degree Angle with the tool’s drive shaft for efficient operation. Due to their design, they are not suitable for thick metal parts and are more suitable for cutting very thin materials. Their design is very simple, so they are affordable and do not require a powerful engine, which reduces costs.

You can easily cut objects in narrow Spaces and tight corners using cutting tools. They are suitable for a variety of materials, including metal, wood, plastic, etc. Due to their small size, they are easy to use and carry.

How Cut Off Tool work

Most cutting tools come with a small disc, usually no more than 3 inches in diameter, best suited for small workpieces and tight Spaces. Due to its small size, it can be easily used in tight Spaces where other tools cannot enter.

Cutting tools can be powered by electricity or air pressure, and there are some battery-operated models, but they are relatively rare and in most cases less powerful. The pneumatic models are the most powerful and are therefore common in car shops.

Electric models are only suitable for small amounts of work. Although they are larger, they are usually not as powerful. Of course, they don’t require the use of an air compressor, which may be an advantage for some buyers.

Main features of Cut Off Tool:

Size and portability: Cutting tools are compact and lightweight, ideal for tasks that require maneuverability and accessibility.

Cutting discs: These tools use thin cutting discs, usually made of abrasives such as alumina. These discs are replaceable and can be easily customized according to the cutting material.

Cutting capability: Cutting tools are ideal for straight line cutting, such as pipes, rods or sheet metal.

Best Use:

Metal fabrication: Cutting tools excel in metal fabrication projects that are essential for precise cutting.

Auto repair: Whether it’s cutting bolts, exhaust pipes or metal panels, these tools are indispensable in the automotive industry.

Pipe engineering: Cutting tools are ideal for handling pipe tasks, including cutting metal pipes and fittings.

Although cutting tools and Angle grinders have some things in common, there are clear differences in their uses and characteristics. When choosing the right tool for your needs, it is crucial to consider your specific task and budget.

Angle Grinder

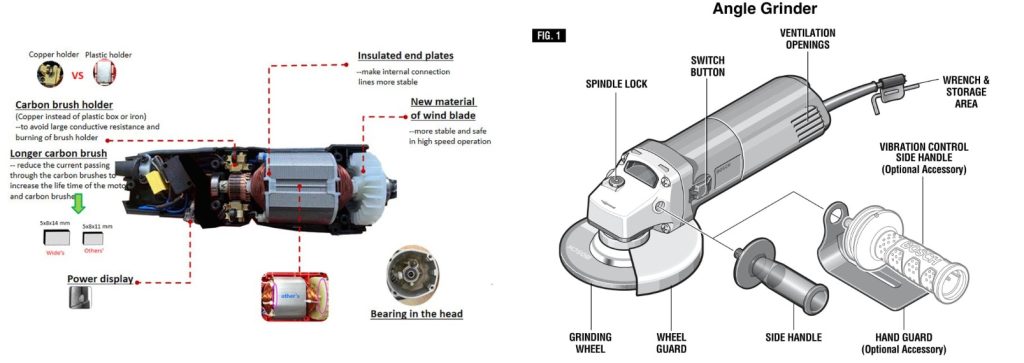

Angle grinder is a multi-functional cutting tool equipped with rotary grinding wheel. The grinding wheel may have a rough edge or surface, making it suitable for a variety of tasks, including cutting, grinding and polishing. The Angle grinder has a wide range of uses because of its various accessories. They are commonly used for grinding and cutting work and can be operated efficiently and seamlessly with both hands.

Angle grinders have powerful motors that can cut a variety of hard materials quickly and precisely. The head is designed at a specific Angle to the drive shaft, allowing you to adjust the cutting Angle and power as needed.

Main features:

- Versatility: The amazing versatility of the Angle grinder makes it easy to switch between different accessories to complete various tasks such as grinding, grinding, polishing and more.

- Adjustable guard: The guard around the Angle mill is usually adjustable to change the direction of sparks and debris, improving safety during operation.

- Power options: The Angle mill is available in both electric and pneumatic (aerodynamic) versions, which can be selected according to different power supplies to provide greater flexibility.

Best application scenario:

- Metal cutting: Angle grinders are suitable for cutting metal, similar to cutting tools. However, due to its versatility, Angle grinders can also play an important role in other situations where multiple tasks need to be performed.

- Surface preparation: Angle grinders equipped with grinding wheels are ideal for jobs such as smoothing welds or preparing painted surfaces.

- Masonry work: By selecting the appropriate accessories, Angle grinders can perform tasks such as cutting bricks, tiles and concrete.

- When working with an Angle grinder, be sure to follow safe operating procedures, wear appropriate personal protective equipment, and ensure that you are familiar with the correct use methods and precautions.

The main difference between an Angle grinder and a Cut Off Tool

Cut Off Tool and Angle grinders are two different tools that differ in function and use.

A cut-off Tool is a compact, one-handed tool designed to Cut or sharpen metal. It has a smaller motor (about 1 HP) and its cutting disc is aligned at right angles to the tool shaft. Cutting tools are suitable for cutting thin metals, such as steel plates. Due to its small size and ease of operation, it is very convenient in narrow Spaces or when cutting fine structures. Cutting tools usually only need to be operated with one hand to complete the job.

An Angle Grinder is a portable power tool that is slightly larger than a cutting tool. It is also known as a side grinder, equipped with a motor power usually between 3 and 7 horsepower, with cutting, shaping, sharpening, grinding and other functions. Angle grinders are suitable for a variety of tasks, including cutting metal, grinding surfaces, polishing and removing materials. Compared with cutting tools, Angle grinders require both hands to operate and have a wider range of uses.

Here are the main differences between cutting tools and Angle grinders:

- Function: The cutting tool is only used for cutting, while the Angle grinder has a wider range of functions and can perform multiple tasks such as cutting, grinding, shaping, sharpening, etc.

- Motor power: Angle grinders are usually equipped with motor power between 3 and 7 horsepower, while the standard power of cutting tools is about 1 horsepower.

- Mode of operation: The cutting tool can be operated with one hand, while the Angle grinder needs to be operated with two hands. Angle mills are larger and may require more control and stability.

- Application scenarios: Cutting tools are suitable for cutting thin metals, while Angle grinders are suitable for a wider range of tasks, including cutting metals, grinding surfaces, polishing and removing materials.

- No matter which tool you choose, safety is always the primary consideration. When using cutting tools or Angle grinders, always wear appropriate personal protective equipment, follow safe operating procedures, and ensure that the working area is stable and clean to minimize the risk of accidents.

How to choose Angle grinder and Cut Off Tool?

There are some important considerations to keep in mind when choosing to use an Angle grinder and cutting tool. If you consider the points listed below, it will help you make your decision.

Scope of application

The fundamental difference between an Angle grinder and a cutting tool is that the former requires only one hand to operate. In particular, if you work in small metal fabrication, this will make it much simpler to use. If most of your manufacturing projects are small scale, you can easily use cutting tools. However, if you are used to cutting large amounts of metal, it is best to use a two-handed Angle grinder.

Application field

The cutting tool limits the scope of work because it is only used to cut certain kinds of metals. Although you can perform many different tasks with an Angle grinder, including cutting, grinding, sanding, polishing, and engraving. If you are sure that you only need to do the cutting work, then you can choose the cutting tool. However, if you like the versatility of power tools, choose an Angle grinder.

Power

No matter what kind of power tool you buy, its speed is determined by its power. This reflects its cutting ability. When you choose higher power, you get higher cutting speed and power. Cutting tools have a smaller power range than Angle grinders. As a result, they can only perform small, low-power cutting tasks.

However, the power of the Angle grinder is three to five times that of the cutting tool. So you can use it for more manufacturing operations.

Positioning

The positioning of power tools is also important, as it affects how convenient you are in completing complex manufacturing tasks. Angle grinders cannot compete with cutting tools for positioning. Their heads are perpendicular to the ground and can be controlled with one hand. Therefore, they can be used in limited Spaces.

Depending on your manufacturing task, you can decide if you want a tool that can handle high-intensity work or operate around tight Spaces.

Security options

You can’t ignore security features. Since you often use metal for cutting and grinding, accidents can easily happen. Therefore, the tool you choose must have specific security features.

In addition, you should take precautions to ensure your safety and the safety features of power tools. This includes wearing safety gear such as gloves, hard helmets, face masks and goggles.

Price

Finally, and most importantly, price is a key factor. It also affects the value your power tools add to your manufacturing tasks. The price range of these products distinguishes them from each other. You can choose according to your financial situation. I recommend choosing the most useful and safest power tool because it is a one-time investment. It will pay off in the long run.

Factors to consider:

- Cost: Due to the larger size and higher motor power, the cost of Angle grinders is usually higher than that of cutting tools. On the other hand, cutting tools are generally cheaper than Angle grinders and require less maintenance.

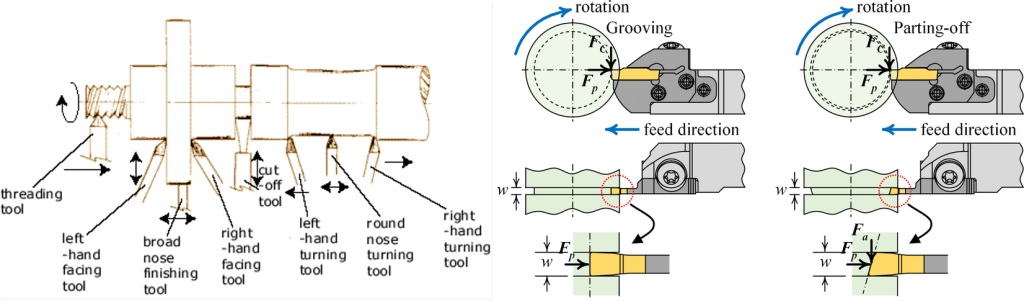

- Wheel orientation: The direction of the cutting wheel used by the Angle grinder and cutting tools is also an important consideration. There are two common wheel directions: straight cut and side cut.

- Straight cut wheels: Straight cut wheels are suitable for vertical cutting tasks, such as cutting pipes or metal rods. Both Angle grinders and cutting tools can use straight cut wheels, but Angle grinders are generally better suited for this type of cutting.

- Side-cut wheels: Side-cut wheels are suitable for horizontal cutting tasks, such as cutting metal plates on a flat surface. Cutting tools are often equipped with side-cut wheels, making them more suitable for this type of cutting.

Therefore, when choosing an Angle grinder or cutting tool, you need to consider your specific cutting needs as well as the required wheel orientation.

These are some of the important factors when choosing an Angle grinder and cutting tool. Evaluate according to your specific needs and budget, and choose the right tool for your job. Always pay attention to safety when using these power tools and follow the manufacturer’s instructions.

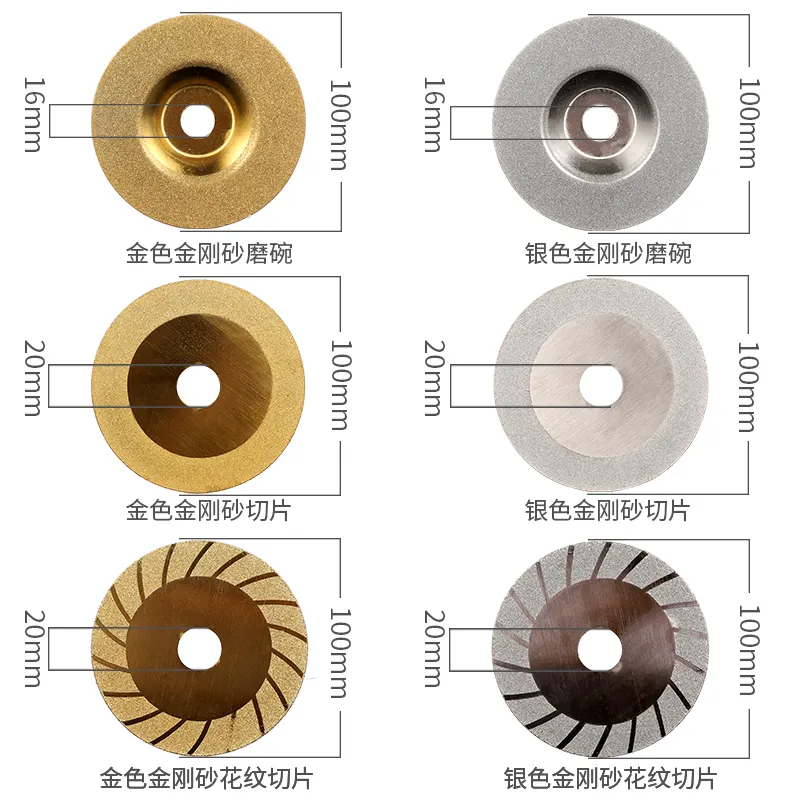

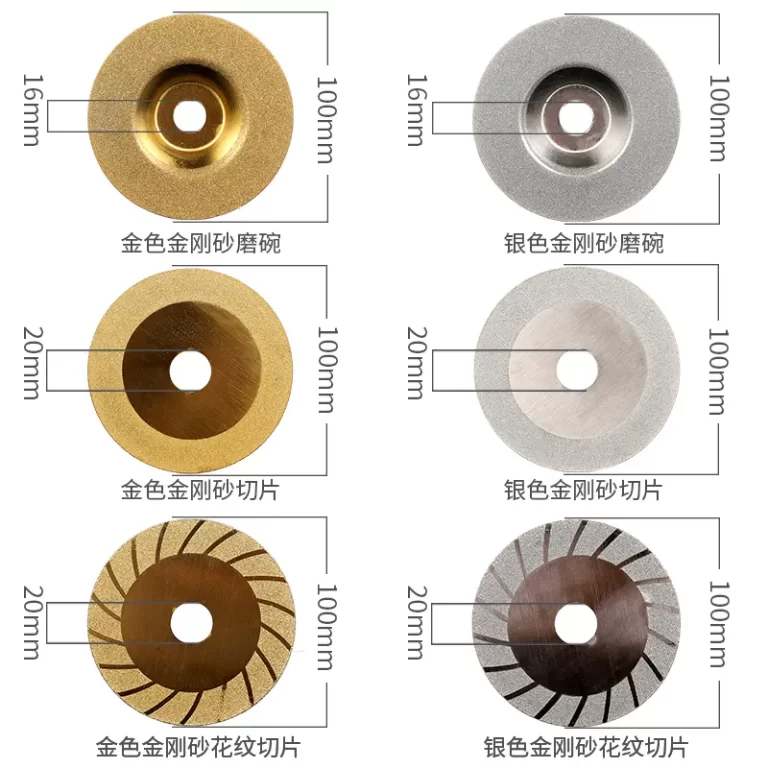

Select the right DISC

Both tools rely on interchangeable discs to perform a variety of tasks. Choosing the right disc for your job is crucial to getting the best results:

- Cutting tool tray: The cutting tray is essential to the cutting tool. These discs come in different thicknesses and compositions to suit the material you are cutting. Thinner discs are ideal for precise cutting, while thicker discs are more durable and suitable for heavier cutting tasks. Make sure you have a range of cutting sheets for different materials such as metal, masonry and even plastic.

- Angle grinder disk: Angle grinder can accommodate a variety of disks, each disk has a specific purpose. Some common discs include:

- Grinding disks: These disks are designed to remove material and smooth surfaces.

- Cutting sheets: Similar to the cutting sheets used in cutting tools, these can cut a variety of materials.

- Impeller: Ideal for finishing and mixing surfaces.

- Grinding disc: Used for grinding wood, metal or other surfaces.

- Wire brush tray: Ideal for rust removal and paint removal.

Select the right Disc size

The disk size of the Angle grinder is usually larger than that of the cutting tool, with a standard size of 4.5 to 9 inches. The power required depends on the material you are working with; For example, thicker materials require more powerful motors, which in turn means bigger and heavier machines. Cutting tools typically have a smaller disk size, ranging from 2 to 4.5 inches, making them easier to control and more portable.

Depth of cutting

Angle grinders offer greater cutting depth than cutting tools and can handle materials up to 9 inches thick. They also have a higher RPM (revolutions per minute), which means they can handle thicker materials faster. Cutting tools, on the other hand, have limited cutting depths and are best suited for thin materials (up to 1/2 inch thick).

Care and maintenance

To extend the life of the tool and ensure optimum performance, regular maintenance is essential:

- Cleaning: After each use, thoroughly clean the tool to remove dust, debris, and metal shavings that can accumulate and affect its function.

- Replace the grinding disc: For both tools, check the cutting or grinding disc regularly for wear. They are replaced when worn to ensure safe and efficient operation.

- Lubrication: If your tool has moving parts such as bearings, use proper lubrication to keep it running smoothly.

- Storage: Store tools in a dry, clean place to prevent rust and damage. Use an appropriate box or toolbox for extra protection.

Skills and experience

Operating both cutting tools and Angle grinders requires a certain level of skill and experience to operate effectively and safely. Although they are user-friendly tools, it is still recommended to familiarize yourself with their operating instructions and take appropriate safety measures, such as wearing protective glasses, gloves, and masks, before using them.

Bottom line: Choosing the right tool depends on your specific needs. If you need to perform precise cutting work, select the cutting tool and the appropriate cutting sheet. If you need to grind, sand, or cut thicker materials, an Angle grinder may be a better choice. No matter which tool you choose, always make sure to follow the operating instructions and safety guidelines to ensure safe operation and the best results.

Project instance

To better illustrate the application of these tools, let’s consider several project scenarios:

Project 1: Metal fence installation

Suppose you are going to install a metal fence around your property. In this case, the cutting tool will be your first choice. Its precision cutting capability is ideal for cleanly cutting metal rods, ensuring accurate and even length. You can also use the tool to score and adjust as needed.

Project 2: DIY terrace renovation

If you’re doing a DIY patio renovation that involves cutting paving materials, sanding uneven surfaces, and removing old mortar, then an Angle grinder will be your tool of choice. Its versatility allows you to switch between cutting and grinding discs and complete a variety of tasks without having to change tools.

I’m in the metal manufacturing business. Early on, we had a grinder made by Black and Decker called the “Wildcat.” It’s an excellent tool, but it requires a wire connection. We are free to use this powerful grinder. It is equipped with many types of grinding stones and grinding discs and is an important step forward for the metal industry. Over time, the platform has expanded to include smaller, lighter models. Now, we see countless different attachments, and the list grows every day.

At some point, I modified a 6 “rubber back pad for sandpaper that was designed for a 3/8” VSR drill bit to fit on my 7 “wildcat grinder. My purpose is to use it for rough grinding of Bondo on metal plates. That was around 1977. It works well, but it’s a little primitive. I tried a few different things until I found something that worked pretty well. And then I didn’t improve it any further. That thing is too heavy for me to put paper on.

Around that time, the first small auxiliary grinding machines began to appear. They developed rapidly. I purchased a 4-1/2-inch model around 1986. It was equipped with rubber pads for thicker metal sandpaper discs that were newly introduced at the time. It wasn’t long before I saw their potential. With these superb tools and an incredible selection of accessories, you can cut, shape, smooth and polish wood, metal, plastic, glass, rubber and everything in between. I have three and they are used a lot in my shop, I now focus on woodworking but use a myriad of different materials in my work. These tools are wonderful and versatile.