Angle Grinder vs Bench Grinder

When undertaking any type of renovation project, an Angle grinder is essential in order to achieve strong polishing or abrasive cutting. However, there is also the option of a bench grinder with a better grinding wheel that sharpens the tool and shapes the metal before proceeding with the welding project.

Both are useful for certain purposes and can be used effectively to achieve your goals. There has been confusion about which is best for your requirements. In this article, we’ll discuss both options to help you make a better choice.

Angle grinders & bench grinders: the basic knowledges

Before diving into the main differences between the two types of grinders, let’s define what each option means and what it is used for. This will give you an idea of what each mill is designed for and which product is best for your project.

What is an Angle grinder?

An Angle grinder is a hand-held rotary tool commonly used for polishing material surfaces, cutting pavers, and sanding. It has the characteristics of fast speed, and is usually used for large-scale and high-intensity work that swing multifunctional tools are not capable of. Other tools, such as the Vibration multitool, cannot handle it.

The tool, available in wired and wireless versions, is a regular feature on construction sites and in many stores. Interchangeable discs are very popular because of the versatility they offer.

How does the Angle grinder work?

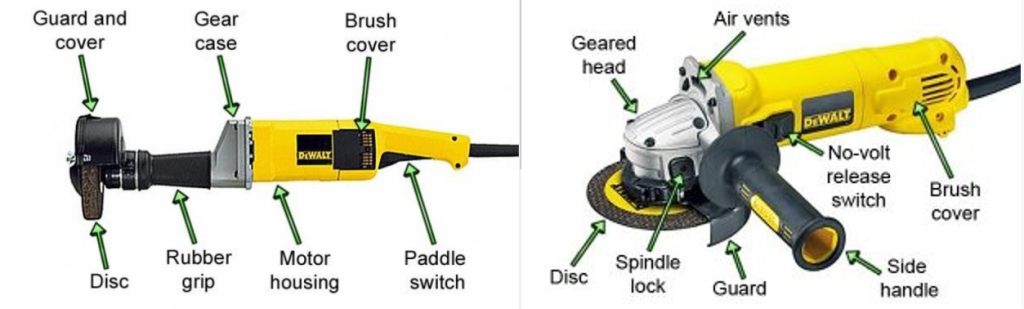

The tool uses a small air compression system or a motor to drive the gear head as well as the spindle. Multiple Angle grinder discs can be secured and connected to the spindle by tightening the screws. When the power is turned on, the disc with the gear head rotates rapidly and the material is then polished, ground or abrasive cut.

What is a bench grinder?

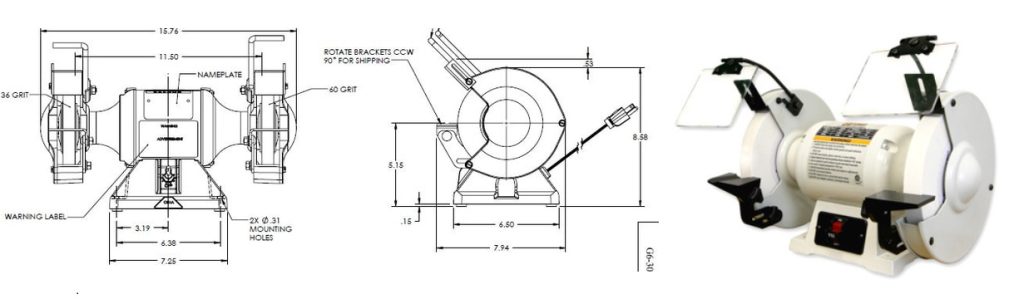

A bench grinder is a grinding tool set on a bench with a uniform grinding wheel. They are mainly used for grinding tools such as chisels, drills and tool heads. In addition, they are used to shape metals to fit welding operations or any project.

In general, they are much less versatile than the former, and they are also less portable.

How does the bench grinder work?

A bench grinder is mounted on a fixed workbench and works similarly to an Angle grinder without cutting capability. It is generally used for polishing, sanding and grinding of various materials. The most common design has the gear head located in the center, with an attached motor and two adjacent wheels.

When the power is on, the motor charges the two wheels and the tool is applied to the material to do the work. Similar to the Angle grinder, the grinding wheel can be replaced according to the user’s requirements.

Comparison of Angle grinder and bench grinder

What are the similarities between Angle grinders and table grinders?

. Use: Both are used for grinding metal. Depending on the wheel you install, both can polish, polish and shape metal and wood.

. User: Both require professional treatment, as Luyang use may cause eye injury or tearing

. Wheels: Each tool option has a different set of wheels to learn about;

. Guards: Using the included guards when using both tools can help protect the user

In short, Angle grinders are portable, with rotating discs that work at high speeds to polish, sand and cut workpiece materials. The bench grinder is fixed with an abrasive rotary grinding stone. They are commonly used for grinding, deburring and sharpening blades, cutting tools and drills. The next section details the main differences between the two tools.

- the working principle: The two tools work in a similar but different way. An Angle grinder is a hand-held tool with discs at different angles that rotate quickly and are applied to the working material. A bench grinder, on the other hand, is a stationary tool with two rapidly rotating grinding wheels that are then applied to the workpiece material. You must pay attention to safety to prevent injury from flying debris in the grinder shield. The grinder guard is located directly behind the gear disc or gear head.

- Portability: the Angle grinder is one of the most portable power tools. They are usually powered by air compression or electricity, so the freedom to move around the location of air compression or power output is limited. It also depends on the length of the air hose or wire at hand. However, advanced Angle grinders are powered by rechargeable batteries, but thus reduce the power output and service life of the machine. Therefore, it is best to use a direct power supply. In contrast, the bench grinder is a stationary tool, which means that it cannot be moved. They are attached to heavy brackets or benches and are difficult to carry. However, the tool is not very heavy and can be moved with a little manpower.

- Use: Angle grinders have a variety of uses on materials such as plastics, concrete, ceramics, wood and metal. It is used for the following purposes:

- Remove paint and rust

- Weld cleaning

- Cut rods, screws and rebar

- Three tripods

- polishing

- grinding

Bench polishers cannot have such a wide range of functions as Angle grinders, but they make up for this with efficiency. Bench grinders can also process plastics, concrete, ceramics, wood and metals. Its general uses are as follows:

- Three tripods

- polishing

- Chamfering and deburring

- Grinding bit

- Lathe tool sharpening

- grinding

- Versatility

Angle grinders are very flexible and can be applied to many different metal sizes. It can be used in metal processing, concrete processing, woodworking and other fields of work. The disc can also be replaced according to the size of the material. Interchangeable discs changed the game. They perform high levels of grinding, grinding and cutting. For example, one of the most popular impellers is not a grinding wheel, but can effectively remove material. It can also be used for carving and woodworking.

Bench grinders, on the other hand, limit their availability and focus on certain tasks. However, there are a variety of grinding wheels available on the market with different functions, thicknesses and roughness to suit applications such as grinding and polishing.

- Power Supply

Another obvious difference between these tools is the power source that drives the tool. The Angle mill is powered by one of the following methods. They are:

- Air compressors for pneumatic Angle mills,

- There is power for the rope Angle grinder, as well

- Rechargeable batteries for cordless Angle grinders.

- Desktop grinders, on the other hand, are usually powered through an electrical outlet.

Step 6: Price

Angle grinders are affordable, with the lowest model available for as little as $20. The cost is affected by the brand, type of power supply, and size. A high-quality Angle grinder, ranging in price from $80 to $300. Benchtop grinders for light tasks start at $50. However, more power and longer life start at $200 and go up to $800 to $1,000.

- Vibration

When using these two tools, you may feel a little vibration due to their speed and power. But importantly, Angle grinders show more vibration than bench grinders.Since the bench grinder is fixed to a flat surface, the weight of the tool and surface reduces vibration, keeping it to a minimum. Now, because the Angle grinder is a hand-held tool, the vibration is large and the stability is poor. Of course, the actual vibration level depends on the exact model as well as the material you are using.

- Wheel speed

In terms of speed, the Angle grinder is much faster than the table grinder. Therefore, if you want your tools to be easy to move and carry, it is recommended to choose an Angle grinder. It’s great for quick work. Small cutting jobs can be done faster and in a matter of minutes. Bench grinders are not as fast, but more accurate.

- Number of wheels

The bench grinder has two wheels that can be used and connected at the same time. In contrast, bench grinders have only one wheel at a time. This is not a significant difference, as it saves the time of switching to a different mill when using an Angle grinder.

- Flexibility

Because the Angle grinder is a portable handheld tool, it has more uses and applications than a desktop grinder, and is suitable for many jobs. Since the bench grinder is fixed, you have to move around it to get the job done. Because of the different angles, Angle grinders can be used for a variety of applications. However, bench grinders are less flexible and can only handle certain tasks.

- Weight

The weight of the Angle grinder is much lighter than that of the table grinder. This makes it easy for users to carry the tool. The average bench grinder weighs about 7 to 8 pounds. However, the bench grinder has a cast iron base and is therefore very heavy. Therefore, the bench grinder is fixed and vibrates less.

- Design

The Angle grinder is designed to fit your hand and comes with a long handle for easy operation. Also remember to reduce vibration. The design of the table grinder is better, because it is characterized by difficult to control the grinding workpiece.

Use of machinery

Although both of these options are grinders that can be used for specific purposes, they do not serve exactly the same purpose.

Bench grinders are ideal for grinding and shaping materials. It’s not exactly a multi-purpose tool. In other words, the Angle grinder is widely used and has a wide range of uses. Among other things, it can cut different materials and is often used in metals because it is strong enough.

Which should I buy, an Angle grinder or a table grinder?

There is no direct answer to this question because it depends on many factors. We’ve charted a clear route for you to find the answer below, with the right tool for your requirements.

When it comes to choosing the option you want, you should think about what you will be using your tool for. If you want to sharpen the blades of a lawn mower or edger, then using a bench grinder will be your best choice.

On the other hand, if you need to cut paving materials or metal, an Angle grinder is a wise choice. This is also a wise choice if you need to bring tools to the job site

The Angle grinder is suitable for the following purposes.

Use cases in different scenarios:

- Used for polishing metal

When using the fish mill for polishing, it is necessary to install the impeller and adjust the speed. For bench grinders, a buffer wheel is included.

Therefore, the Angle grinder is a better metal polishing machine because the tool can not only polish, but also smooth the surface to enhance the color of the material - For sharpening (blades, drills, knives, axes)

Angle grinder and table grinder blade sharpening?

A bench grinder is ideal when you sharpen tools that require both hands to remain steady to get a perfect edge.

On the other hand, when items are too large for a table grinder to sand easily, an Angle grinder can work well as a knife sharpener, as long as the tool is secured to prevent the blade from slipping.

In this case, the stability, slower speed or variable speed of the bench grinder make the tool ideal for grinding hand tools or blades, as the wheel can easily remove thicker layers of steel faster than any whetstone.

However, you will need to sand the blade on the whetstone for final finishing. - Grind metal and coagulants

The Angle mill uses a stone grinding wheel to grind the cement. For coagulants, it is best to moisten the coagulants to reduce heat and dust. For grinding metal, use a thick grinding wheel.

A bench grinder, on the other hand, can grind even the hardest materials, making the tool ideal for grinding purposes, but only for smaller objects.

Due to the higher stability of the desktop grinder, we find it best suited for precision work, process or mechanical engineering work. - Cut metal and stone

The diamond wheel of an Angle grinder can cut stone and coagulant, but ideally you must first wet the stone 4o

Thin abrasive cutting wheel can cut any thickness of metal.

Ideally, Angle grinders are ideal for cutting because the tools are smaller, more flexible, and more portable - Remove rust

Angle grinders are ideal for removing rust because the rust layer is thin and there is no need to damage the metal underneath. On the other hand, if the grinding wheel speed is slow, the bench grinder can remove rust on small surfaces.

Overall, bench grinders are very effective for rust removal on small tools, as coarse sand can easily remove thicker layers of rust with finer control.

For large tools like shovels and axes, Angle grinders do a better job of removing rust and reaching the entire surface.

When to use the Angle grinder?

The lightweight size and flexibility of the Angle mill for cutting metal in dry movement enables the Angle mill to operate in the material and make the desired cuts when needed.

. When removing old paint from metal surfaces, Angle grinders work quickly and efficiently without damaging the metal with paint strippers.

. Mill garden tools.

. Mainly used for cutting or grinding coagulants.

Conclusion

Angle grinders and bench polishers are both very useful tools that can be used for many different tasks. For absolute flexibility, both tools are advantageous, but if you have the budget, then you should choose the tool that is better suited to the task at hand.

We’ve done our best to resolve all your questions about Angle grinders and bench grinders, but if you still have questions, please mention them in the comments section below.

Both bench polishers and Angle grinders are great tools for some jobs, but if you need to decide which is better for the job you need to do, then knowing the differences between them can help you decide on the best option for your use.

Handheld grinders allow for more movement and better angles, but benchtop grinders are very precise and have two wheels that can be used at the same time. Both have advantages and disadvantages.

A quick recap, for all your grinding and polishing needs, an Angle grinder is your best choice. For all cutting, sharpening and forming needs, a bench grinder will be the best choice. And also other grinders, like grinding mill for food, chemicals.