Can you cut marble with an angle grinder?

Here’s a detailed, reader-friendly translation and expansion of your original text, with clear explanations and logical flow:

Cutting Marble with an Angle Grinder: A Practical Guide

Yes, an angle grinder can be used to cut marble, but it requires specific diamond blades and strict safety precautions due to the tool’s inherent limitations in precision and control. Before operation, always inspect the grinder for a securely attached guard and ensure the cutting disc is properly mounted. Below is a comprehensive breakdown of the key considerations:

1. Tool Compatibility: Why Diamond Blades Are Essential

Angle grinders can cut marble effectively when fitted with a diamond-embedded cutting disc (typically 1–2 mm thick). These blades are designed for stonework because:

- Material Hardness: Diamond (Mohs 10) outperforms marble (Mohs 3–4), whereas standard metal-cutting discs will shatter the stone or wear down instantly.

- RPM Requirements: Most angle grinders operate at 10,000–12,000 RPM, which is sufficient for shallow cuts but inefficient for long, straight lines compared to a dedicated masonry saw.

- Depth Limitations: Ideal for thin slabs (<50 mm) or detail work (e.g., trimming edges, cutting sink holes). For thicker materials, a bridge saw or wet tile cutter is preferable.

Note: Never use damaged or worn discs, as they may explode under high-speed rotation.

2. Safety & Operational Best Practices

Personal Protection:

- Eye and lung safety: Wear impact-resistant goggles and an N95 respirator to shield against marble dust and flying debris.

- Clothing: Avoid loose sleeves, jewelry, or gloves (which can get caught in the tool). Tie back long hair.

- Workspace prep: Clear flammable materials and secure the marble with non-slip clamps to prevent shifting mid-cut.

Tool Handling:

- Startup control: Angle grinders often “kick back” when turned on. Grip firmly with both hands and position yourself so the blade spins away from your body.

- Cooling breaks: Pause every 30 minutes to prevent motor overheating. Let the tool run idle briefly to cool down.

Cutting Technique:

- Speed and pressure: Push the grinder gently to avoid blade stalling or marble chipping. Let the diamond blade do the work—forcing it causes jagged edges.

- Cooling aid: Spray water periodically to reduce heat buildup, which can crack marble or degrade the blade. A partner can help with a spray bottle while you cut.

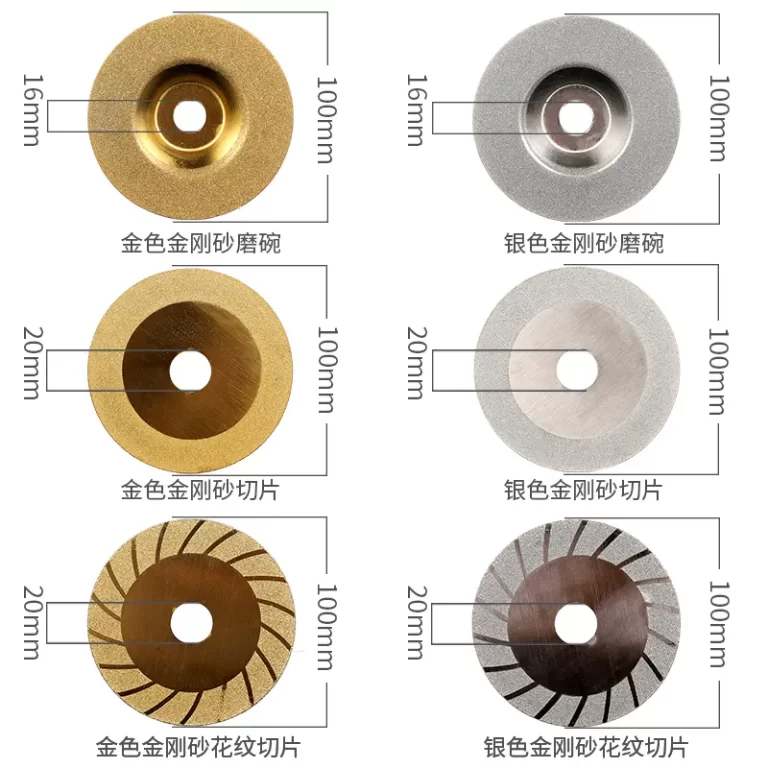

3. Blade Selection & Machine Specs

- Diamond blade types: Choose a continuous-rim blade for smoother cuts or a segmented blade for faster (but rougher) results. Match the grit to your marble’s hardness (softer stone = finer grit).

- Grinder requirements:

- Power: ≥800W motor (e.g., DeWalt DWE402 or Makita GA4030).

- RPM: 10,000–12,000 RPM (lower speeds risk blade binding; higher speeds may overheat stone).

4. Limitations & Alternatives

- Precision issues: Angle grinders have a ±2 mm margin of error—unsuitable for projects requiring hairline accuracy (e.g., intricate tilework). For such tasks, a waterjet cutter (±0.1 mm) is better.

- Repairing mistakes: If the marble chips, smooth the edge with a 200-grit diamond polishing pad.

- Large-scale jobs: Cutting full slabs? Opt for a bridge saw (depth capacity >100 mm) or wet circular saw to save time and ensure straight lines.

When to Use (and Avoid) an Angle Grinder for Marble

- Recommended for: Small repairs, curved cuts, or on-site adjustments (e.g., shortening countertops, creating notches).

- Avoid for: Production-grade work (e.g., kitchen backsplash tiling) or thick-stone fabrication.

Final Tip: Always do a test cut on scrap marble to fine-tune your technique before tackling the main project.

This version prioritizes clarity, eliminates bullet-point fragmentation, and groups related concepts into cohesive paragraphs while retaining all technical details. Let me know if you’d like further adjustments!