Is marble easier to cut than granite?

Yes, marble is significantly easier to cut than granite due to its lower hardness and different mineral composition. This fundamental difference impacts everything from the tools required and the speed of cutting to the cost and potential for do-it-yourself projects. Understanding the “why” and “how” behind this requires a look at the stones themselves and the practical realities of working with them.

Understanding the Core Difference: Hardness and Composition

The key reason marble is easier to work with lies in its fundamental geology. Marble is primarily composed of calcite (calcium carbonate), a relatively soft mineral. On the Mohs scale of mineral hardness, which ranks minerals from 1 (talc) to 10 (diamond), marble typically falls between 3 and 5. Granite, in contrast, is an igneous rock packed with much harder minerals like quartz (Mohs 7) and feldspar (Mohs 6), giving it an overall hardness of 6 to 7. Think of it like trying to carve soap (marble) versus trying to carve a piece of glass or hardened plastic (granite). The harder the material, the more resistance it offers to cutting tools, demanding greater force, specialized equipment, and wearing down tools much faster. Quartz, ubiquitous in granite, is particularly abrasive and rapidly dulls cutting edges not specifically designed to handle it. Marble’s calcite offers far less resistance, allowing cutting tools to bite in and remove material more efficiently.

How Physical Properties Dictate the Cutting Process

This difference in hardness translates directly into the practicalities of cutting:

- Force and Tool Wear: Cutting granite requires powerful machines exerting significant pressure on ultra-hard diamond blades or abrasive water jets. Even with diamond, the blades wear down remarkably quickly due to the constant abrasion against quartz. You might need to change blades or sharpen segments far more often on a granite job compared to marble. Cutting marble demands less brute force. While still requiring diamond tools for efficiency and clean cuts, the blades last considerably longer, and smaller machines can sometimes suffice. That heavy-duty grinding machine needed to shape granite edges might be overkill for marble, where lighter tools can be effective.

- Speed and Efficiency: All else being equal, you can cut marble faster than granite. The blade encounters less resistance, allowing for higher feed rates without risking excessive heat buildup or damaging the stone. This speed translates to lower labor costs and faster project completion times when working with marble.

- Heat Sensitivity and Cooling: While both stones can generate dangerous heat during dry cutting, marble is generally less prone to catastrophic thermal shock cracking than some granites. However, heat is still an enemy to the diamond bond in saw blades. Water cooling is crucial for both, but the lower cutting forces needed for marble often mean less friction-induced heat is generated in the first place. Efficient cooling systems, whether integrated into a large bridge saw or applied via a spray bottle on a handheld cutter, are vital for blade life and cut quality on either stone.

- Risk of Chipping and Breakage: Marble’s relative softness is a double-edged sword. While easier to cut, it’s also more prone to chipping or “spalling” along the cut edge, especially if the blade is dull, the feed rate is too fast, or the stone has internal weaknesses. Granite, being harder and tougher, typically produces cleaner, sharper edges during cutting but requires significantly more effort to achieve. Supporting the stone properly during the cut is critical for both to prevent breakage, but thin marble slabs are especially vulnerable.

Essential Tools for Cutting: Marble vs. Granite

The core requirement for cutting both stones effectively is diamond. Diamond is the only material hard enough to consistently abrade granite and efficient enough for professional marble work. However, the type and robustness of the equipment differ:

- Marble Focused Tools:

- Handheld Wet Saws/Profile Grinders: Often used for sink cutouts, trimming edges, or small modifications on installed marble countertops. These are relatively portable tools with water feeds. While they can cut granite, the process is slow, hard on the tool, and requires frequent blade changes. They are well-suited to marble’s softer nature.

- Small Bridge Saws: Smaller fabrication shops might use less powerful bridge saws primarily designed for marble and softer stones. They can handle granite for occasional small jobs but aren’t ideal for high-volume granite production.

- Softer Bond Diamond Blades: Blades designed for marble use a softer metal bond matrix. This allows the worn diamond grit to shed more easily, exposing fresh, sharp diamonds constantly. Using a blade designed for granite on marble would wear excessively fast without cutting efficiently. Using a blade designed for marble on granite would likely glaze over (the bond won’t wear to expose new diamonds) or break due to the higher forces required.

- Specialized Grinding/Polishing Tools: Finishing marble edges often involves a progression of diamond polishing pads, starting with coarse grits for shaping (using a variable speed grinding machine or polisher) and moving to finer grits for a high shine. Marble polishes to a brilliant luster relatively easily.

- Granite Focused Tools:

- Industrial Bridge Saws: Cutting granite slabs efficiently requires heavy-duty, high-horsepower bridge saws with robust frames and powerful motors to drive large diameter diamond blades through the incredibly hard stone. Water cooling systems are large and integral. Think of these as the workhorses of stone shops.

- CNC Routers/Waterjets: For complex shapes, intricate sink cutouts, or detailed edge profiles in granite, CNC (Computer Numerical Control) machines with diamond tooling or high-pressure abrasive waterjets are almost essential. The precision and ability to handle the hardness make them indispensable for granite fabrication. Waterjets are excellent for both stones but are particularly valuable for granite due to its hardness and the complexity often desired.

- Hard Bond Diamond Blades: Granite blades use a much harder metal bond matrix. This bond holds onto the diamond grit longer, necessary to withstand the extreme abrasion of quartz. These blades are designed for high pressure and high torque.

- Powerful Grinders/Polishers: Shaping and polishing granite edges requires heavy-duty grinders with significant torque. The polishing process is more time-consuming and requires more steps than marble to achieve a comparable shine due to granite’s crystalline structure. A standard grinding machine used for metalwork wouldn’t stand a chance; stone-specific, high-power tools are mandatory.

Practical Considerations: Cost, Skill, and Safety

The ease of cutting marble has tangible real-world implications:

- Cost: Fabricating a marble countertop is generally less expensive than fabricating a granite countertop of the same size and complexity. This stems directly from the lower tool wear (longer blade life), faster cutting times (less labor), and potentially less specialized machinery required. Replacing a worn-out diamond blade for granite cutting happens far more frequently than for marble. Waterjet cutting, while precise for both, also takes longer and uses more abrasive for granite, increasing costs.

- Skill Level & DIY Potential: Cutting simple shapes in marble (like a straight countertop section) is feasible for a skilled DIYer with the right tools (a quality wet saw, proper diamond blade, clamps, safety gear, and patience). Cutting granite effectively and safely, however, is strongly discouraged for amateurs. The power required, the potential for blade damage or binding, the weight of the slabs, and the specialized techniques make it a job best left to professionals with industrial equipment. Even setting up the workspace safely for granite cutting is more demanding.

- Safety: Cutting any stone generates hazardous silica dust (crystalline silica), a known carcinogen when inhaled. Dry cutting is extremely dangerous and should be avoided whenever possible. Wet cutting is mandatory to suppress dust. Granite, containing much more quartz, produces silica dust more readily and in higher concentrations than marble during dry cutting. Regardless of the stone, rigorous safety protocols are non-negotiable: full respiratory protection (N95 masks are insufficient; use P100 or a supplied-air respirator for significant work), eye protection, hearing protection, proper ventilation, and wet methods. Connecting your grinding machine or saw to a HEPA-filtered dust extraction system designed for silica is highly recommended even during wet cutting for secondary capture. The heavy weight of slabs also requires careful handling to prevent crushing injuries – granite slabs are notably heavier than marble slabs of the same size.

- The “Charger” Factor: Portability is a consideration. While large bridge saws need fixed, powerful electrical connections, smaller handheld tools like angle grinders (used cautiously for trimming) or profile grinders often use rechargeable batteries. The runtime and power of the charger pack become crucial. A high-capacity, fast-charging battery system is vital for efficiency, especially on job sites without easy power access. However, for the sustained power needed to cut granite effectively, corded electric tools are almost always necessary. Cutting granite demands continuous high torque that would rapidly deplete even the best battery charger packs. Marble cutting with smaller handheld tools is more compatible with battery operation for shorter tasks.

Choosing the Right Stone: Beyond Cutability

While ease of cutting is a major factor for fabricators and installers, the end-user’s choice between marble and granite hinges on their application and priorities:

- Marble’s Allure: Chosen primarily for its stunning, unique veining and classic elegance. Ideal for low to moderate traffic areas like bathroom vanities, fireplace surrounds, wall cladding, and decorative elements where its beauty shines. Requires more maintenance (sealing) to prevent staining.

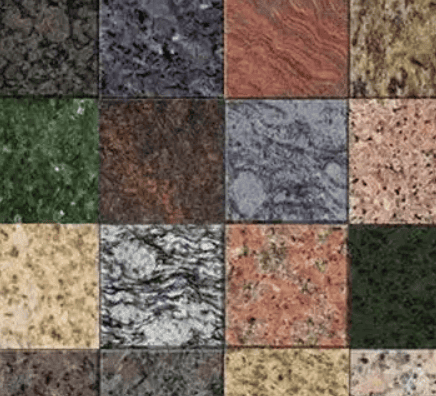

- Granite’s Strength: The go-to choice for high-durability applications. Its extreme hardness makes it highly resistant to scratches, heat (hot pots can be placed directly on it), and wear. Perfect for busy kitchen countertops, high-traffic flooring, and outdoor applications. Generally requires less frequent sealing than marble and offers superior stain resistance when properly sealed. Its appearance is more granular and speckled.

Conclusion

The verdict is clear: marble is demonstrably easier to cut, shape, and polish than granite. This advantage stems directly from its lower mineral hardness, primarily calcite versus granite’s quartz and feldspar. This translates into faster cutting speeds, less wear on diamond blades and equipment (like a grinding machine), lower fabrication costs, and even a degree of feasibility for skilled DIY work on simple marble projects. Granite demands heavy-duty industrial machinery, specialized hard-bond diamond blades, and professional expertise due to its inherent toughness and abrasiveness. While both stones require diamond tooling, water cooling, and rigorous safety precautions (especially for silica dust), the sheer force and tool wear involved in granite fabrication set it apart. Ultimately, the choice between marble and granite should balance the desired aesthetics, the functional demands of the installation location, maintenance expectations, and budget – with the understanding that granite’s superior durability comes with a higher fabrication cost rooted in its challenging nature to cut.