Is it better to cut marble wet or dry?

For cutting marble, dry cutting using specialized “Dry-Cut King” blades is generally the superior and recommended method, while wet cutting requires extreme caution to avoid equipment damage or serious safety hazards. This central truth stems from the fundamental differences in how these techniques interact with marble’s properties. Let’s delve deep into the mechanics, advantages, risks, and optimal applications to understand why dry cutting deserves the crown for most marble work.

Unpacking Dry Cutting: Speed, Stability, and Blade Longevity

Dry cutting, as the name implies, involves slicing through marble without adding any water during the process. This method is particularly well-suited for materials like marble and granite, which fall into the medium-to-high hardness category. The magic lies in the specialized design of dry-cut blades, like the “Dry-Cut King.” These blades are engineered with specific bond formulations and diamond grit concentrations optimized to handle the intense friction and heat generated. The bond, the material holding the diamond particles, is designed to wear away at a controlled rate, constantly exposing fresh, sharp diamonds to the cutting surface. This engineering allows for remarkably fast feed rates – you can push the saw through the stone more aggressively. Furthermore, the blade exhibits exceptional cutting stability, meaning it vibrates less and tracks straighter, resulting in cleaner cuts and significantly reduced wobble that can damage both the blade and the material. Crucially, because there’s no water to suddenly cool the blade or create hydraulic forces, the wear on the diamonds and the bond is more consistent and predictable. This controlled wear directly translates to a longer blade life and enhanced operational safety, as there’s no risk of the thermal shock that plagues wet methods when misapplied. The absence of water also eliminates messy slurry and simplifies the worksite setup, making dry cutting inherently more efficient for many on-site and workshop applications.

The Hidden Dangers of Wet Cutting: Efficiency Loss and Serious Risks

While wet cutting is often instinctively thought of as “cooler” and therefore safer, this is a dangerous misconception when applied to marble cutting with standard blades. The core problem lies in the dramatic thermal shock that occurs when water meets an extremely hot diamond blade slicing through stone. Marble cutting generates intense, localized heat at the point of contact between the diamond grit and the stone. When water is introduced – even a small amount – onto this superheated zone, it causes rapid and uneven cooling. Imagine pouring cold water onto a hot glass dish; it shatters. Similarly, this thermal shock creates immense stress within the blade’s metal core and the segments (the parts holding the diamonds). This stress can warp the blade core, causing it to wobble violently or even shatter, turning the blade into deadly shrapnel. The sudden cooling also causes the metal in the segments to contract rapidly, potentially cracking the segment structure or ripping diamonds out prematurely, drastically accelerating blade wear. Beyond the shock hazard, using water inappropriately creates a sludge of stone particles and water. This abrasive slurry gets forced between the blade and the stone, increasing drag and friction. This extra resistance forces the saw to work harder, slowing down the cutting speed significantly and putting additional strain on the saw motor. In essence, improper wet cutting makes the job slower, destroys blades faster, and creates severe safety hazards including blade disintegration and potential kickback.

Essential Safeguards: Prioritizing Dry Blades and Smart Practices

Given the clear advantages of dry cutting and the risks of wet, the primary rule is straightforward: Always choose a blade specifically designed for dry cutting marble, like the “Dry-Cut King” type. These blades are constructed with heat-dissipating segment designs (like laser-welded segments or wider gullets for air flow) and bonds formulated to withstand the high dry-cutting temperatures. Their core is engineered for stability under thermal stress. The second critical rule is: Avoid adding water during cutting unless absolutely necessary for specific scenarios. Water should never be used as a standard cooling method for dry-cut blades on marble. If, during exceptionally long cuts or very thick material, you observe excessive heat buildup (smoke or a strong burning smell is a clear indicator), and only if the blade manufacturer explicitly permits it, you might apply a minimal, controlled mist of water directly to the blade’s gullets (the spaces between segments) away from the immediate cutting zone. This is not drenching the blade or the cut; it’s a light spray aimed solely at aiding air cooling. Never flood the cut. Finally, ensure your saw has excellent airflow. Dry cutting relies on air to cool the blade. Never obstruct the saw’s cooling vents. Equally important is managing the workload. Avoid prolonged, continuous cutting sessions. Give the saw and blade regular breaks to allow heat to dissipate naturally. Plan your cuts strategically to incorporate these cooling pauses, protecting both your valuable equipment and ensuring operator safety. Forcing a saw to cut non-stop is a surefire way to overheat the blade and motor, leading to premature failure and potential hazards.

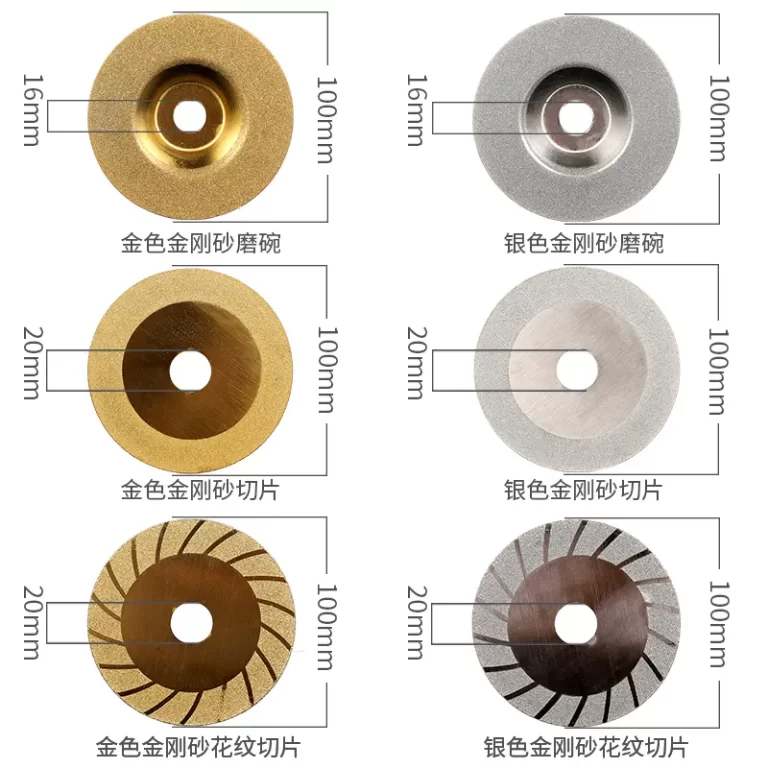

Demystifying the Blades: Dry-Cut vs. Wet-Cut Design Differences

The divergence between dry-cut and wet-cut blades goes far beyond just the label; it’s rooted in their fundamental design philosophy, dictated by their operating environment. Dry-cut blades face the challenge of operating in a high-heat, air-cooled environment. To survive this, they typically use a softer metal bond. This softer bond wears down more readily as the blade heats up, which is actually beneficial because it continuously exposes fresh, sharp diamond crystals to the cutting surface, maintaining cutting efficiency. Their segment design often features larger or specially shaped gullets to maximize airflow around the blade, acting like tiny fans to pull heat away. Laser welding of segments to the core is also common for dry blades, as it creates a stronger, more heat-resistant connection than traditional silver brazing. The core steel itself is often thicker or of a specific grade to resist warping under thermal stress. Wet-cut blades, conversely, operate in a cooler, water-lubricated environment. They usually employ a harder bond material because the water prevents the excessive heat that would otherwise glaze a hard bond (where the bond gets polished smooth and stops wearing, trapping dull diamonds). The water carries away the ground stone particles (swarf), so gullet design focuses more on efficient swarf removal rather than maximizing air cooling. Brazing (using a filler metal) is a more common attachment method for wet-blade segments since the operating temperatures are lower. Crucially, wet blades are not designed to handle the extreme, uneven temperatures of dry cutting. Using a wet blade dry, even briefly, can cause rapid overheating, segment loss, core warping, and catastrophic failure due to the mismatch between their design and the harsh dry-cutting environment.

The Visual and Practical Outcome: How Cutting Method Affects the Stone

The choice between dry and wet cutting significantly impacts the final look and quality of the marble edge. Dry cutting, operating at higher temperatures, produces a cut edge that is generally very clean but might exhibit a very slight “burnt” or crystalline appearance right at the very edge under close inspection. This is often imperceptible in many applications. Crucially, because no water interacts with the stone, the marble’s inherent color, veining patterns, and natural texture remain completely pristine and unaltered. The stone’s beauty is fully preserved. However, the flip side is that dry cutting tends to leave the stone’s surface more “open.” Any existing minor pits, fissures, or natural variations within the marble are more likely to be visible on the cut edge. While this showcases the stone’s natural character, it might not be desirable for applications demanding a perfectly uniform appearance. Wet cutting, with its constant water flow acting as a lubricant and coolant, typically produces a visibly smoother and more polished-looking cut edge. The water helps wash away debris and can slightly “polish” the very edge during the cutting process. Furthermore, the water can wash fine particles into tiny surface imperfections on the cut edge, potentially masking minor pits or hairline fissures that would be visible after dry cutting. This results in a more consistent, “closed” surface appearance. However, there’s a potential aesthetic trade-off: the water can sometimes interact with minerals in certain marbles, potentially causing slight leaching or subtle dulling of the natural colors along the cut edge, especially noticeable in highly porous or reactive stones. The water essentially creates a slurry that can be forced into the stone’s microscopic pores near the cut, potentially affecting its visual purity.

Choosing the Right Tool for the Job: Matching Method to Application

Understanding the performance and aesthetic outcomes naturally leads to selecting the appropriate method for the project:

- Dry Cutting Shines: This method excels where preserving the marble’s raw, natural beauty is paramount. It’s ideal for sculptural work, architectural features like cladding or mantelpieces where the natural edge might be visible, rustic flooring or wall applications celebrating texture, and any restoration project requiring the new piece to perfectly match the aged, unaltered character of existing marble. Its speed and portability make it indispensable for kitchen countertop fabrication and installation, templating, and most on-site cutting tasks where water access is inconvenient or messy. If the final edge will be polished, honed, or otherwise finished after cutting, the slight “openness” of a dry-cut edge is irrelevant, making dry cutting the efficient default choice.

- Wet Cutting’s Niche: Wet cutting finds its primary role where an exceptionally smooth, consistent cut edge is required straight from the saw, and where absolute precision (±0.5mm tolerance) is critical, such as for intricate mosaics or tightly fitted joints. It’s essential in environments where dust control is non-negotiable – indoors, in poorly ventilated areas, or on sensitive sites like hospitals or data centers. For cutting very thick marble slabs or performing exceptionally long continuous cuts where even a specialized dry blade might overheat, a properly executed wet cut with a wet-rated blade can be necessary. It’s also preferred for materials known to be highly sensitive to heat or prone to chipping with dry methods, or where masking minor surface imperfections on the cut edge is desirable before any further finishing.

Conclusion: Embracing the Dry-Cut Standard with Informed Exceptions

The evidence overwhelmingly supports dry cutting with specialized blades like the “Dry-Cut King” as the standard, safest, and most efficient method for the vast majority of marble cutting tasks. It delivers faster cuts, longer blade life, superior stability, and preserves the stone’s natural beauty, all while simplifying the work process. Wet cutting, while crucial for dust suppression in confined spaces or achieving ultra-high precision with specific equipment, carries significant risks of blade damage and safety hazards if not executed meticulously with the correct wet-rated blade and constant water flow. Always prioritize using a high-quality dry-cut blade designed for marble, avoid water unless strictly necessary and approved by the blade manufacturer (applied minimally and carefully), ensure excellent saw ventilation, and incorporate cooling breaks. By respecting the fundamental differences between dry and wet cutting mechanics and choosing the method strategically based on the stone, the environment, and the desired finish, you ensure optimal results, maximum safety, and efficient project completion. Remember: when it comes to marble, dry cutting, done right, is truly king.