Angle Grinder Disc Types and Blade Type

Angle Grinder Disc Type

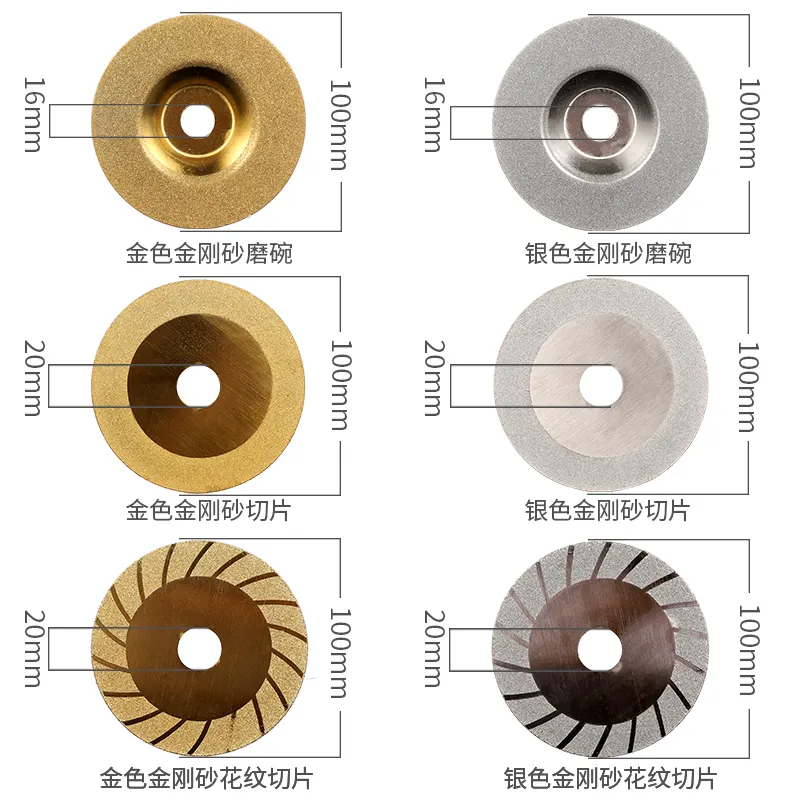

1.Grinding wheel

The grinding wheel is one of the most commonly used disks in the Angle grinder. It is mainly used for the processing and dressing of metal, wood and stone. Grinding wheel materials are diverse, common alumina, silicon carbide, yttrium oxide, etc., different materials of grinding wheels are suitable for different workpieces.

2. Polishing plate

The surface of the polished plate is smooth and delicate, mainly used for improving the finish and surface treatment of metal products. The polished plate is made of high-strength fiber material and needs to be installed on the Angle grinder before use. When in use, add polishing liquid to increase the polishing effect.

3. Wire brush

Wire brushes are usually used to treat rough surfaces into good condition, such as brushing off rust caused by rusty metal parts. Its steel wire material is mostly steel wire or copper wire, there are different specifications and sizes and thickness to deal with different situations.

4. Emery cloth tray

Emery cloth tray is mainly used for fine metal surface grinding and trimming. Its emery cloth selection is more delicate, and the slight concave and convex part of the surface can be polished off during the processing, so as to achieve the overall brightness and smoothness.

In general, the disk type of the Angle grinder has its own strengths, and it can be processed and processed accordingly for different workpieces. Whether it is home maintenance or industrial production, different disks have an indispensable role.

Angle Grinder Blade Type

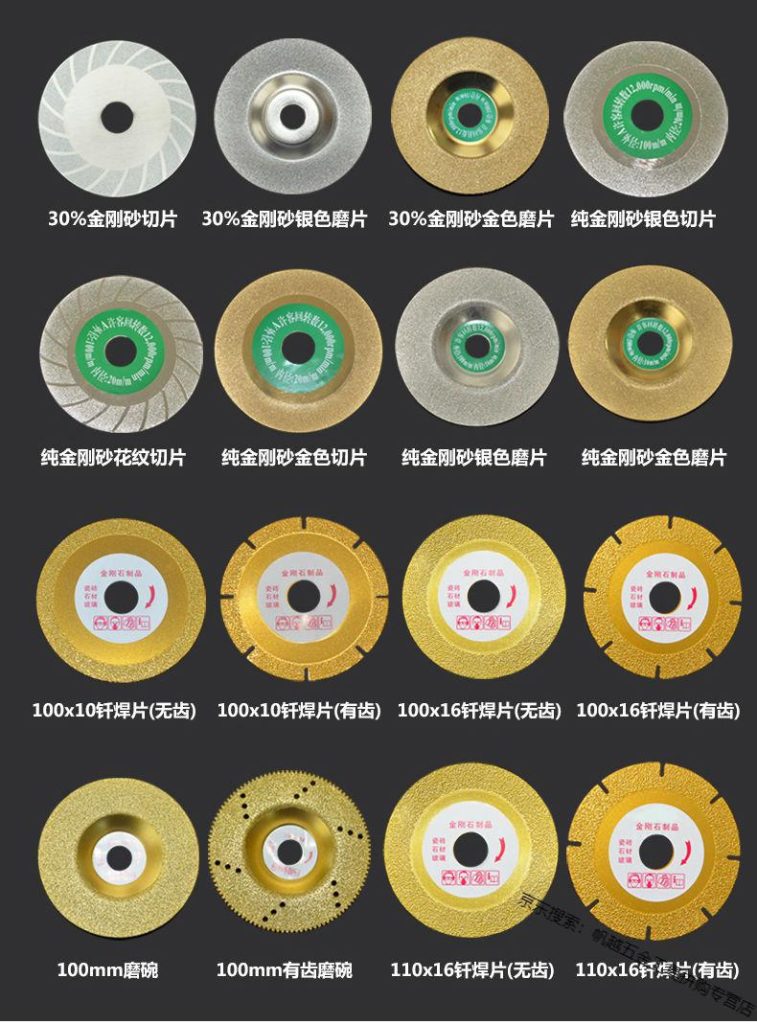

There are three kinds of Angle grinder blades: diamond blade, tungsten carbide blade and steel blade.

Diamond blade

Diamond blade is one of the most common and most commonly used Angle grinder blades, its hardness is very high, can cut a variety of hardness materials, especially suitable for cutting glass, ceramic tiles, ceramics and other extremely hard materials. The diamond blade has two kinds of single-sided blade and double-sided blade, of which the double-sided blade has a longer service life.

Tungsten carbide blade

Tungsten carbide blade is another common Angle grinder blade, its hardness is higher than ordinary steel blade, but slightly lower than diamond blade, suitable for cutting a variety of metal materials, especially tungsten carbide, seamless steel pipe, copper pipe, aluminum, iron and so on. Tungsten carbide blade has better cutting performance and longer service life than ordinary steel blade.

Steel blade

The steel blade is the most basic Angle grinder blade, which is very suitable for cutting iron plate, steel pipe, steel and so on. Although the hardness of steel blade is not as good as that of diamond blade and tungsten carbide blade, it is still widely used in some light cutting work due to its wide range of application and relatively low price.

In general, different types of Angle grinder blades are suitable for different materials, and choosing the right blade can improve work efficiency and save costs. When using the Angle grinder, the appropriate blade should be selected according to the hardness of the material and the cutting requirements, while paying attention to safe operation to avoid accidents.

Click to see other questions about Angle grinder: